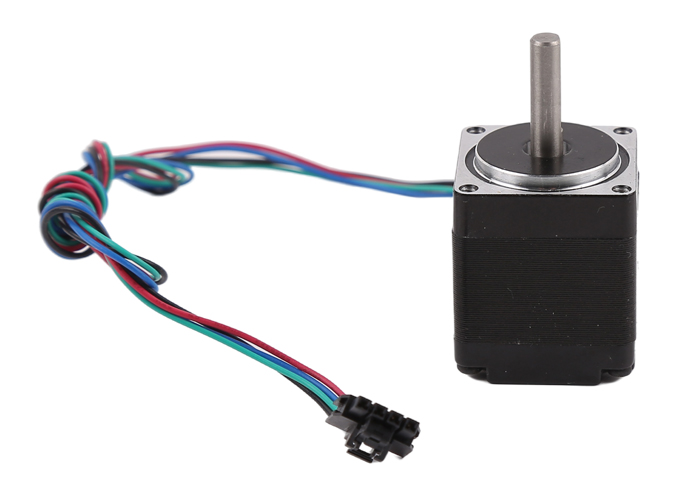

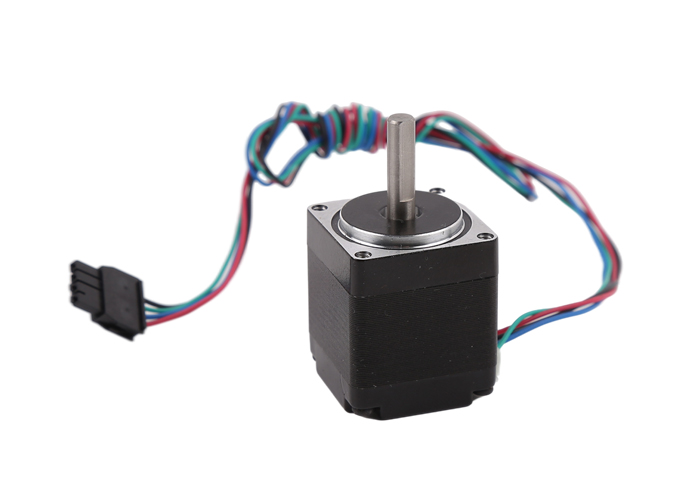

The 28 stepper motor is a small stepper motor, and the "28" in its name usually refers to the motor's outer diameter size of 28 mm. A stepper motor is an electric motor that converts electrical pulse signals into precise mechanical movements. It can achieve precise position control and speed control by accepting one pulse signal at a time and driving the rotor to move by a fixed angle (called the step angle).

In 28 stepper motors, this miniaturisation makes them suitable for applications where space is limited and precision positioning control is required, such as office automation equipment, precision instruments, electronic equipment, 3D printing equipment and lightweight robots. Depending on the design, 28 stepper motors can have different step angles (e.g., 1.8° or 0.9°) and may be equipped with windings with different numbers of phases (two-phase and four-phase are common) to provide different performance characteristics. In addition, 28 stepper motors are typically used with a driver to optimise the motor's operating performance, including smoothness, noise, heat generation and torque output, by adjusting the current level and control algorithms.

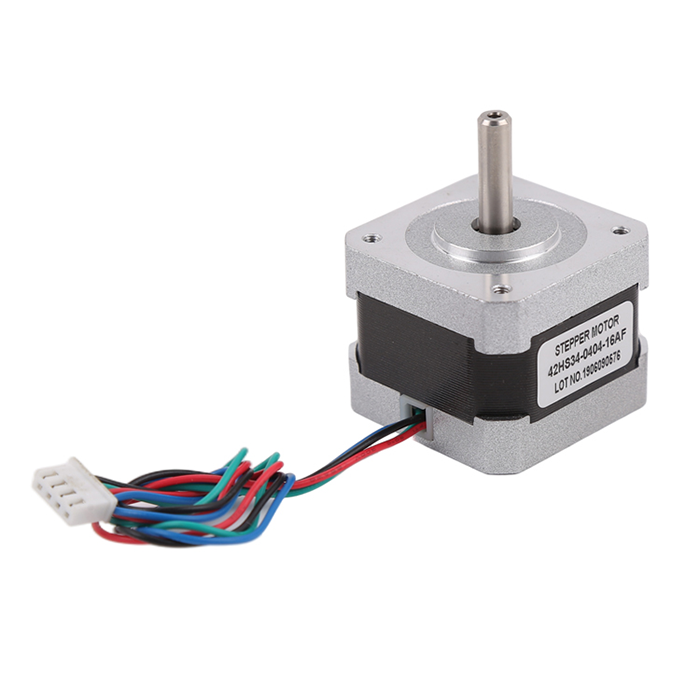

The 42 stepper motor is a size specification stepper motor, and the "42" in its name refers to the 42 mm diameter of its housing or mounting flange. A stepper motor is an electric motor that converts electrical pulse signals into discrete steps of motion, and the angle of rotation and speed of the motor shaft can be precisely controlled by controlling the number and frequency of input pulses.

42 stepper motors typically have a larger size and mass compared to smaller sizes such as 28 stepper motors, and are therefore able to provide a higher torque output capacity, making them more suitable for applications that require larger power drives. These motors are used in a wide range of applications such as automation equipment, 3D printers, robotics, precision instruments, industrial production equipment as well as large office automation installations that require precise position control and drive for medium to large loads.

42 Stepper motors can likewise be divided into different numbers of phases (commonly two and four) depending on the design and are available with different step angles (e.g. 1.8°, 0.9° or even smaller subdivisions). In practice, 42 stepper motors are often used in conjunction with a suitable driver in order to achieve better performance. Current, interpolation and other parameters can be set to optimise efficiency, smoothness and noise reduction.

三、The main differences between a 28 stepper motor and a 42 stepper motor are size, torque output, application, and some performance parameters:

1, Size:

-28 stepper motor: refers to a stepper motor with a mounting flange or chassis OD size of approximately 28mm, which is smaller and suitable for use in applications where space is limited and size is critical.

-42 stepper motors: stepper motors with a mounting flange or housing O.D. size of 42mm, which are larger compared to 28 stepper motors, and are capable of providing greater torque.

2. Torque output:

-28 stepper motor: Due to its small size and light weight, the maximum output torque is usually small and suitable for light load or precision positioning control, such as in small equipment, precision instruments or consumer electronics.

-42 stepper motor: the torque output is relatively large, generally up to 0.5NM or even higher, suitable for occasions requiring larger driving force or higher load capacity, such as 3D printers, automation equipment, industrial control systems, and so on.

3. Performance characteristics:

-The working principle of both is the same, both through the pulse signal to accurately control the angle and position, with open-loop control, no cumulative error and other characteristics.

-Relation between speed and torque, 42 stepper motor may be able to provide higher and stable torque under certain power limitation because of its larger physical size and internal design.

4. application scenarios:

-28 stepper motors are more suitable for application environments where miniaturisation, low power consumption and high precision are required.

-42 stepper motors are more suitable for applications that require a larger range of motion and thrust due to their larger size and stronger torque output.

To summarise, the difference between 28 stepper motors and 42 stepper motors is mainly in the physical dimensions, the maximum torque that can be supplied and the different areas of application that are determined as a result. The selection should be based on a combination of torque, speed, space size and other factors required for the actual application.

Post time: May-09-2024