In the ever-evolving landscape of engineering and technology, precision is often the differentiating factor that sets excellence apart. Whether in robotics, automation, or any field requiring precise control of motion, the choice of the right motor can be paramount. Among the myriad options available, the 15mm Gear Stepper Motor emerges as a true powerhouse, unleashing unprecedented levels of precision and control. In this essay, we will delve into the world of the 15mm Gear Stepper Motor, exploring its significance and the ways it empowers industries to attain precision beyond imagination.

The Essence of Precision

Precision, in engineering terms, is the ability to consistently achieve accurate and desired outcomes. It's the capability to control movement, positioning, and tasks with an exactness that leaves no room for error. Whether it's guiding a surgical robot's delicate movements or ensuring a 3D printer constructs a masterpiece, precision is the cornerstone of success.

The Role of Stepper Motors

Stepper motors have long been the preferred choice for applications that demand precision. These motors divide a full rotation into a series of discrete steps, providing predictable and controlled movements. However, not all stepper motors are created equal, and when it comes to the pursuit of submicron precision, the 15mm Gear Stepper Motor takes center stage.

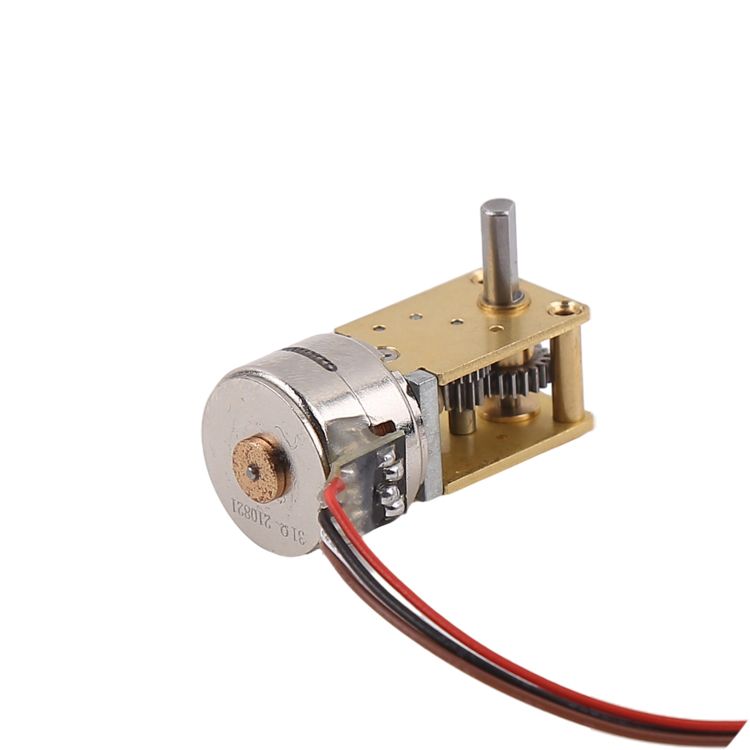

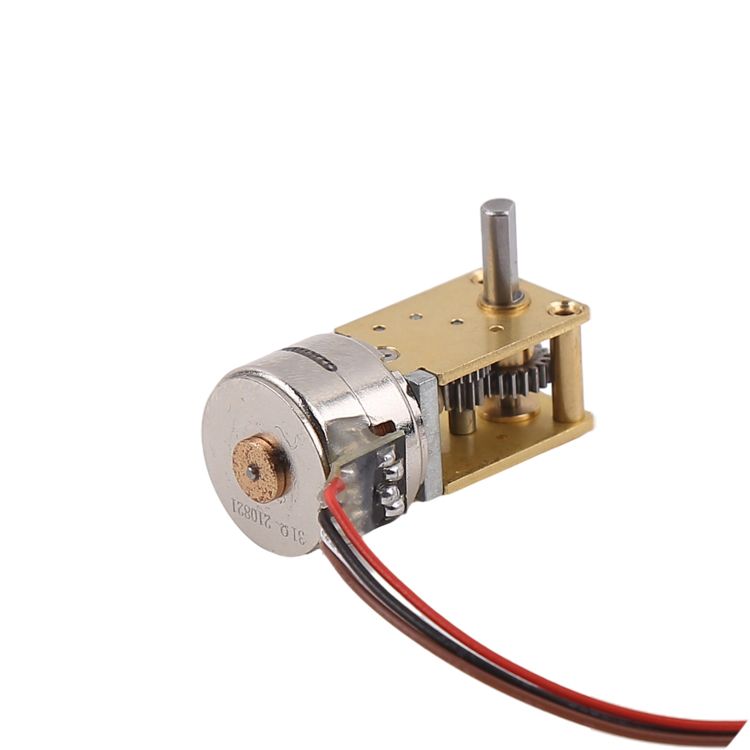

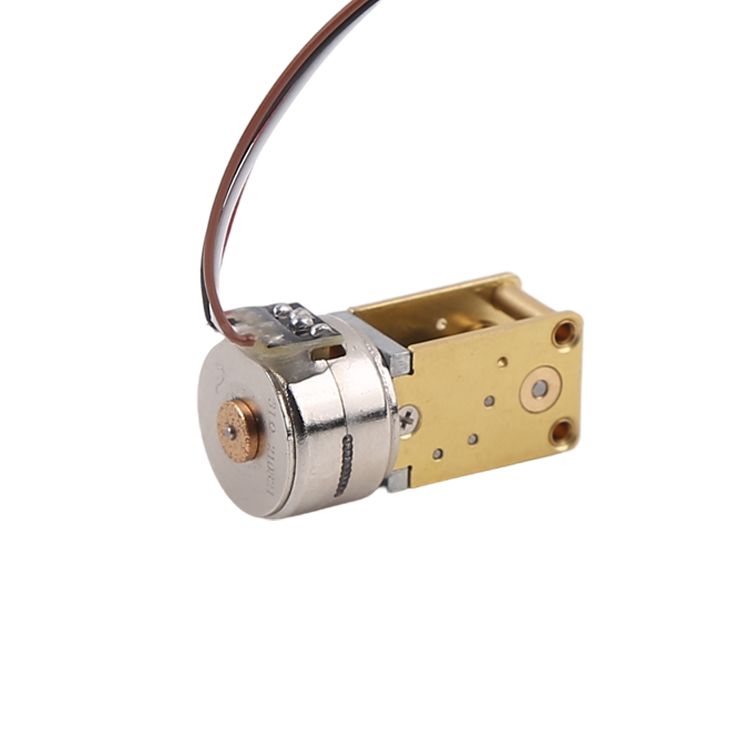

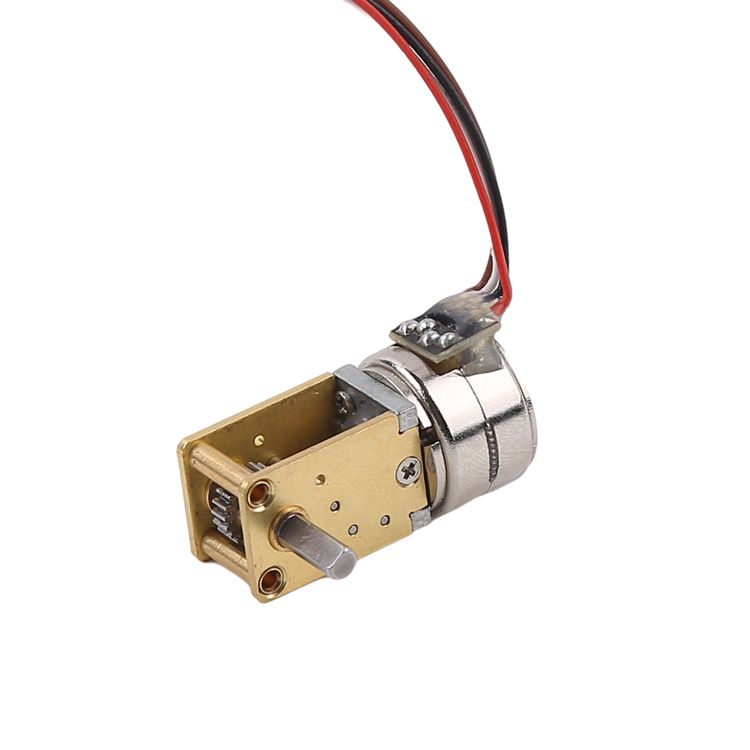

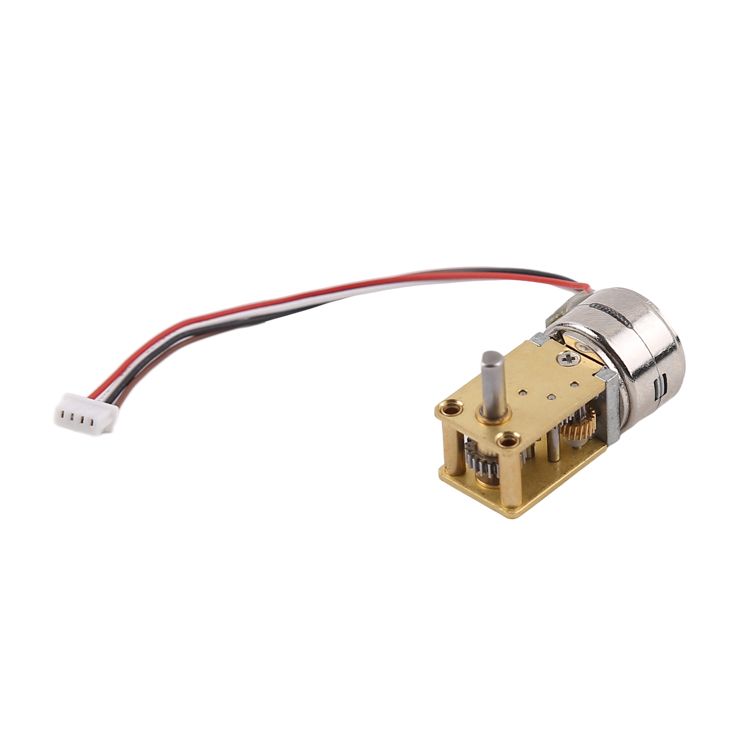

Meet the 15mm Gear Stepper Motor

The 15mm Gear Stepper Motor is a specialized breed, meticulously designed to achieve levels of precision that were once considered unattainable. What sets it apart from its counterparts is its integrated gearing mechanism. This mechanism magnifies the precision of the motor's movement by reducing the angular resolution. In simpler terms, it means that each step of the motor corresponds to a smaller angle of rotation, enabling minute and highly accurate movements.

The Marvel of Gearing Mechanisms

The magic of the 15mm Gear Stepper Motor lies within its gearing mechanism. Gears, often referred to as gearheads, are used to amplify the motor's accuracy. This arrangement multiplies the number of steps per revolution, translating to finer control. As a result, these motors can achieve submicron accuracy, where movements are measured in fractions of a degree. This level of precision opens doors to a myriad of applications that were once deemed impossible.

Applications Beyond Imagination

The applications of the 15mm Gear Stepper Motor are as diverse as they are impactful. In the world of medical robotics, where precision is a matter of life and death, these motors guide surgical instruments with the utmost accuracy, enabling minimally invasive procedures. In the realm of aerospace, they play a pivotal role in stabilizing guidance systems, ensuring the safety of pilots and passengers alike. Even in the intricate world of 3D printing, these motors contribute to the creation of intricate and flawless objects, elevating the quality of the final product.

Selection and Integration

Choosing the right 15mm Gear Stepper Motor involves understanding the specific requirements of the application. Factors such as torque, speed, and resolution must be carefully considered. Additionally, integrating these motors into existing systems demands expertise in control interfaces and precise mounting to guarantee optimal performance.

Fine-Tuning for Perfection

To truly unleash the potential of a 15mm Gear Stepper Motor, fine-tuning is essential. Calibration and optimization, often involving feedback loops like encoders or resolvers, are performed to achieve submicron accuracy. These processes ensure that the motor operates precisely as intended, eliminating any deviations.

Conclusion

In the quest for precision in engineering and technology, the 15mm Gear Stepper Motor stands as a symbol of excellence. Its ability to achieve submicron accuracy, coupled with its compact size, makes it an invaluable tool in a wide range of industries. As technology continues to advance, the 15mm Gear Stepper Motor will continue to push the boundaries of what is possible, unleashing precision beyond imagination and shaping the future of precision engineering.

Post time: Oct-17-2023